Stylo Design Team

Greenwood Task Chair.

Ideation.

For this project, my design team and I (Chapin Henry and Elliott Bryan) were tasked with creating a chair using greenwood sourced from Virginia Tech’s campus. The chair was designed for a dormitory communal space, with an emphasis on minimizing the use of glue and highlighting joinery techniques. During our initial research, we observed that existing furniture in these spaces was frequently rearranged and repurposed by students. In response, we pursued the development of a lightweight “task” chair—designed to be task-oriented, multi-functional, and easily moved to accommodate a variety of activities within the space.

We explored form development through sketching and CAD, with particular attention to the chair’s profile. Constructability was a central consideration throughout the ideation process, as greenwood presents unique challenges in fabrication. Our primary objective was to develop a form that balanced strength, durability, and lightweight performance.

Prototyping.

The most significant component of our research was an ergonomic study. Our first prototype was a highly adjustable plywood chair, which allowed us to evaluate comfort across a range of seating configurations and accommodate various body sizes. Building on these insights, we then developed a more form-oriented working prototype to refine the design.

Rendered Model.

Building on the insights gained from our prototypes, we refined the design and developed the final model. Rendering the CAD model allowed us to visualize the product in its intended materials and effectively communicate our final design intent to the client.

Joinery.

This design incorporates several types of joinery. The front legs are connected using a mortise-and-tenon joint reinforced with a peg for stability. Both the seat and backrest are secured with through pegs that pass through the frame and adjoining components. The focal point of the chair is the rear, three-part joint, which integrates an inset metal bracket bolted into place. The exposed metal contrasts with the maple, creating a striking visual detail that serves as the centerpiece of the design.

This design incorporates several irregularly shaped components that required a high level of craftsmanship to produce. To achieve accuracy, we created full-scale (1:1) templates of each piece, which were then used as guides during the cutting process. This approach enabled us to achieve relatively precise cuts by hand.

Planning for Build.

Final Prototype.

Crafting the final prototype presented significant challenges, as working with greenwood involves a steep learning curve. After extensive time in the woodshop and multiple iterations of key components, we successfully produced a final product that aligned precisely with our design intent.

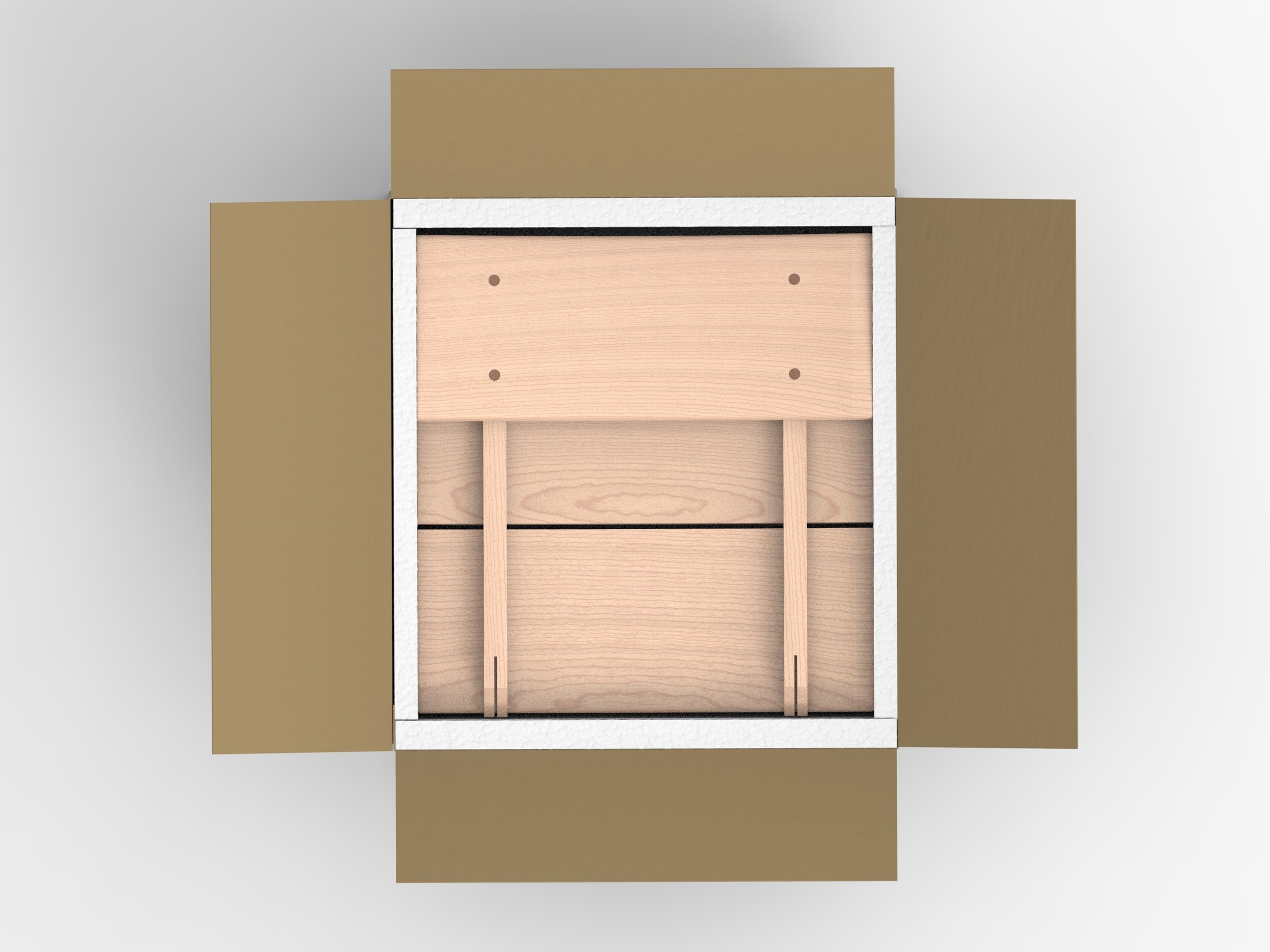

Thinking Packaging.

Considering how this product might be packaged and shipped globally generated valuable insights. Designing furniture for consumer assembly requires additional attention to joinery methods. The rear joint’s metal bracket enables the chair to be disassembled for shipping and easily reassembled by the user after purchase.